Automated visual industrial quality control systems for precision stamping parts are transforming the manufacturing industry by providing higher accuracy and efficiency in the inspection process. These systems use cameras and sensors to capture images of stamped parts, which are then processed and analyzed using computer vision software, image processing algorithms, and machine learning.

By implementing these systems, Feng-yu precision stamping parts manufacturers can enhance the quality control processes for precision stamping parts manufacturing while reducing labor costs and increasing productivity.

How Automated Visual Industrial Quality Control Systems Work?

Automated visual industrial quality control systems work through a series of steps that involve capturing images of stamped parts, processing and analyzing the images, comparing them against pre-set quality standards, making automated decisions and taking action, and providing real-time alerts and notifications. Here's a more detailed breakdown of each step:

- Capturing images of stamped parts: The first step involves capturing high-quality images of the stamped parts using cameras and lighting systems that are specifically designed for industrial applications. These images are then transferred to a computer or a central processing unit (CPU).

- Image processing and analysis: The next step involves processing and analyzing the images using advanced algorithms and machine learning techniques. This includes identifying and segmenting different regions of interest, detecting defects or anomalies, and extracting relevant features and parameters.

- Comparing against pre-set quality standards: Once the images have been analyzed, the system compares the results against pre-set quality standards or specifications. These standards can include parameters such as size, shape, color, texture, and position. Any deviations or non-conformities are flagged for further inspection or action.

- Automated decision-making and action: Based on the results of the comparison, the system makes automated decisions and takes appropriate action. This can include sorting out defective parts, diverting them for rework or repair, or stopping the production process if necessary. The system can also provide feedback to the operators or the production line for continuous improvement.

- Real-time alerts and notifications: Finally, the system provides real-time alerts and notifications to the relevant stakeholders, including operators, supervisors, quality control personnel, or management. This can include visual or audible alarms, email or text notifications, or dashboard displays that show the status of the production process and the quality performance metrics.

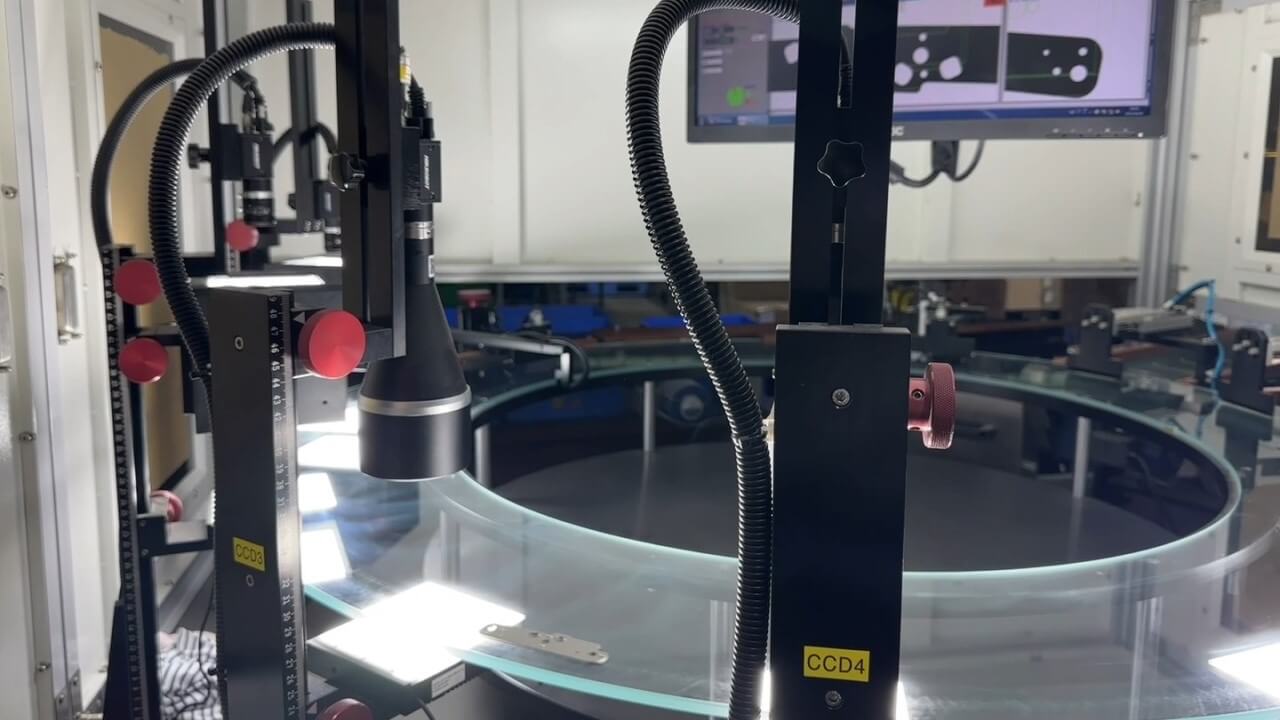

Video of Automated Visual Industrial Quality Control Systems for Precision Stamping

Benefits of Automated Visual Industrial Quality Control Systems for Precision Stamping

An automated visual industrial quality control system can provide several benefits for precision stamping parts, including:

- Improved Accuracy: Automated visual inspection systems use advanced image processing algorithms and machine learning techniques to detect even minor defects and deviations that may not be visible to the human eye. This can improve the accuracy of quality control, reducing the risk of defective parts being released to the market.

- Increased Efficiency: Automating the inspection process can significantly reduce the time and resources required for quality control. By automating the inspection process, you can achieve consistent and reliable results without the need for human intervention. This can free up resources for other critical tasks, such as design and production.

- Cost Savings: Implementing an automated visual inspection system can reduce the need for manual labor, resulting in cost savings in terms of wages, training, and benefits. Moreover, early detection of defects and non-conformities can save costs related to product recalls, warranty claims, and customer dissatisfaction.

- Real-Time Monitoring: Automated inspection system can provide real-time monitoring of the production process, ensuring that the quality standards are being met at all times. This can enable prompt intervention if any issues arise, reducing the risk of defects and increasing customer satisfaction.

- Consistent Quality: Automated visual inspection system can ensure consistent quality, regardless of the volume or complexity of the production process. This can help maintain the reputation of the manufacturer for delivering high-quality products to the market.

Industrial Application of Higher Precision Stamping

Automated visual industrial quality control systems can help Feng-yu precision stamping parts manufacturers to achieve higher levels of precision and quality in their stamping parts, which can be beneficial for a range of industries including the automotive, electronics, medical device, and architectural industries.

Automotive Industry

In the automotive industry, for example, stamping parts with high precision and quality is critical for ensuring the safety and performance of vehicles. Components such as chassis, body panels, and engine parts must meet strict tolerances and specifications to ensure that they function correctly and withstand the stresses of everyday use.

Electronics Industry

In the electronics industry, stamping parts with high precision and quality is essential for ensuring that electronic devices operate reliably and efficiently. Components such as connectors, switches, and stamped heat sinks must be manufactured to tight tolerances and specifications to ensure that they function correctly and provide optimal performance.

Medical Device Industry

In the medical device industry, stamping parts with high precision and quality is critical for ensuring patient safety and product efficacy. Components such as diagnostic equipment must meet strict tolerances and specifications to ensure that they function correctly and perform their intended functions.

Architectural Industry

In the architectural industry, stamping parts with high precision and quality is essential for ensuring that building components such as facades, cladding, and roofing systems are durable, weather-resistant, and aesthetically pleasing. These components must be manufactured to tight tolerances and specifications to ensure that they fit together correctly and provide the desired functionality and appearance.

Conclusion

Overall, automated visual industrial quality control systems leverage the power of image processing, machine learning, and automation to provide accurate, efficient, reliable quality control, save costs, provide real-time monitoring, and ensure consistent quality for precision stamping parts.

By using an automated visual industrial quality control system, Feng-yu precision stamping parts manufacturers can produce high-quality stamping parts that meet the demanding requirements of a range of industries, including the automotive industry, electronics industry, medical device industry, and architectural industry, ensuring customer satisfaction and long-term success.

If you have any precision metal stamping needs, welcome to contact us.

In the past, Feng-Yu has been focusing on completing the customer's entrustment, committed to the improvement of processing technology, and accumulated its own strength.