Metal Stamping Service and Cutsom Solution

Feng Yu is a distinguished custom metal stamping service company, specializing in providing high-quality, tailor-made solutions to meet each customer's specific needs. Leveraging advanced technologies and accumulated expertise, we ensure excellence in every aspect of our services.

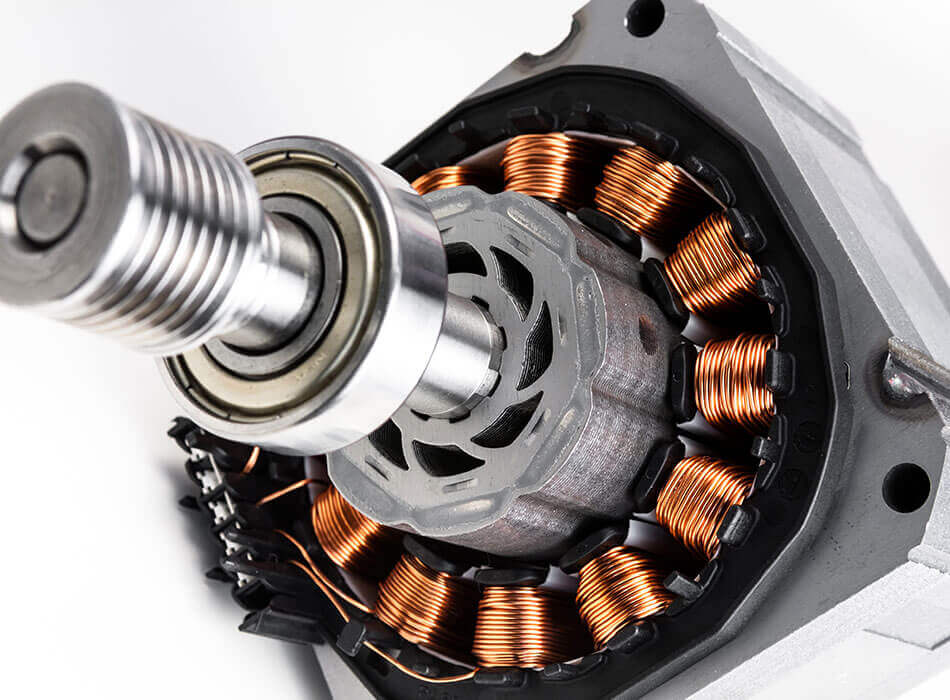

Stamping

MAD Group

Feng Yu Metal Stamping uses professional and precise stamping technology to transform materials into various die shapes, such as embossing, stretching, cutting, stretching, forming and other stamping shapes and sizes, according to customer needs and products. In this way, we plan to meet the your specific needs, carry out customized production and tailor-made your satisfactory finished products.

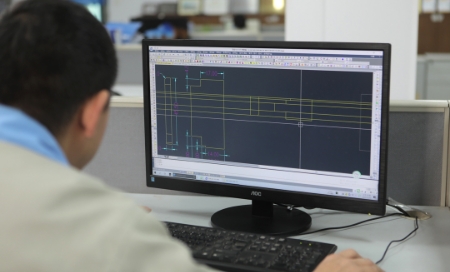

3D CAD/CAM

MAD Group

We use 3D CAD/CAM to process various irregular shaped products. We generate 3D data from drawings provided by customers, create programs and perform machining.

Test

Staff

At Feng Yu , we focus on creating our own standard inspection procedures. In addition, we carefully inspect all processed products for each stage at our in-house inspection site, we also check with high precision that the quality of the processed products is up to the standards after completion.

Production Management System

General Affairs Division

By introducing the special production control systems specially to single-piece processing and small batch processing, we have built a system that can respond to strict delivery requirements and ultra-short delivery requirements. Since everything is built and managed on the local network, data such as new products and confidential drawing data received from customers are not leaked to a third party. In addition, we have achieved a reliable and accurate production system by uniformly managing the arrangement of materials and orders from our partners. When defects occur, defect data is captured by the production control system and shared internally to improve the skills of all employees.

Other Processed Products and Finishing

General Affairs Section

At Feng Yu, we help our customers to collect various products from them at once. We have a very broad network across the country, due to our 50+ years of experience and achievements. Since our partners are professionals on precision machining, welding and base fabrication, laser machining and precision sheet metal machining, gear machining, gun drilling, special grinding, rubber baking, brazing, laser welding, various switchboards and controls by our partners, we Feng Yu are familiar with the methods and contents of the production and assembly of many machined boards. We are also familiar with a wide range of finishing treatments such as various electroplating and alumite treatments, various quenching treatments according to various coatings and materials, and various coatings such as Teflon. We will determine and propose an optimal processing method suitable for the purpose of use of the customer's product, including material, processing method, finishing process, and according to the strength of the product, the appearance of the finished product. During this process, we maintain a constant attention with everything related to the product before it reaches the customer.

The Process of Metal Stamping Service Project

Feng Yu has accumulated a solid experience and has polished a warm and professional approach with both old and new customers.

STEP 1

Make a Demand

After receiving customer's request within 1-2 working days, reply to the customer and make an interview.

STEP 2

Official Search

According to the requirements of international test specifications, search and confirm the content with customers, or provide factory test specifications by customers.

STEP 3

Planning Proposal

Depending on the customer's requirements and specifications, Feng Yu will plan the imported test products or the finished products.

STEP 4

Contract Signed

Both parties agreed on the specifications and quotations, and signed the contract.

STEP 5

Planning Process

In response to the demand for the finished products made by Feng Yu, Feng Yu will further provide a production plan after the contract is signed, and list the details and display the design drawings.

STEP 6

Medium-term Acceptance

After the production of the equipment is completed, the customer will be invited to carry out the inspection in the factory or to the original factory abroad, and make a pre-delivery memorandum.

STEP 7

Delivery Acceptance

Arrange colleagues to connect with customers to check the products and order the delivery products before shipping.

STEP 8

After-sale Correction

Feng Yu collects customer suggestions and understands inconveniences, and corrects them within the original expected specifications.

STEP 9

After-sale Service

Feng Yu also provides out-of-warranty service contract to improve product life cycle.

Stamping Mold and Die Related Process

Let our service and quality bring you relief and confidence.

Design Mold and Die Development Process - New product design management flow chart.

Responsible person: Sales Division

Responsible person: Sales Division, Design Division

Remarks : The Sales Team will review the design with the client

The Design Division will review the Mold and Die Technology/Quality Assurance

Remarks : The Sales Team will review the design with the client

The Design Division will review the Mold and Die Technology/Quality Assurance

Person in charge: Design Division

Person in charge: Mold Section

Person in charge: Quality Assurance Section

Responsible Person: Modeling Class

Responsible person: quality assurance class, Sales Division

Responsible person: Sales Division

Person in charge: Production Management

Mold and Die Assembly Process

After the design is completed, purchase the template for the mold and die process

Mold and die matching set

Mould trial maintenance

Sample review and testing

Completed

Mold and Die Maintenance Process

After the on-site production mold and die is defective, the operator will issue a bill for maintenance

After the technician receives the order, it will be repaired according to the damage of the mold and die

After being repaired, it will be sent to the quality control inspection

After the quality control inspection is confirmed, we will notify the production department to start the production

Mold and Die Damage Repair Process

Stamping production anomaly

Issue "Mold Repair Order" to the Mold Section

Review existing mold and die repair plans and formulate new maintenance strategies

After the mold and die maintenance personnel confirms that the maintenance is completed, we will proceed to notify the quality control verification personnel

After the quality control is confirmed, we will notify the production department to start the production

Production Department will notify the Injection Molding Section about the Production Process

Pick up

Baking

Upper Die

Adjust the Machine

Quality Confirmation

Start Production

The Product is Placed in the Absorbent Box After Processing

Quality Control Inspection

Packed Into Storage

Applications

With superior metal stamping service, Feng Yu produces top-quality hardware components for various applications, showcasing exceptional precision capabilities.