No matter in terms of operation technology or safety, the metal stamping process should meet the corresponding requirements, starting from its technical measures. You should know that the so-called metal stamping is a process of deforming or breaking iron, aluminum, copper, and other plates and dissimilar materials to a certain shape and size by using a punch and a mold.

It can be seen that there are some similarities between metal stamping and sheet metal forming, but there are slight differences because sheet metal forming is carried out with sheet metal, thin-walled tubes, thin profiles, etc. as raw materials, in this case, the deformation in the direction of the thick plate is generally not considered.

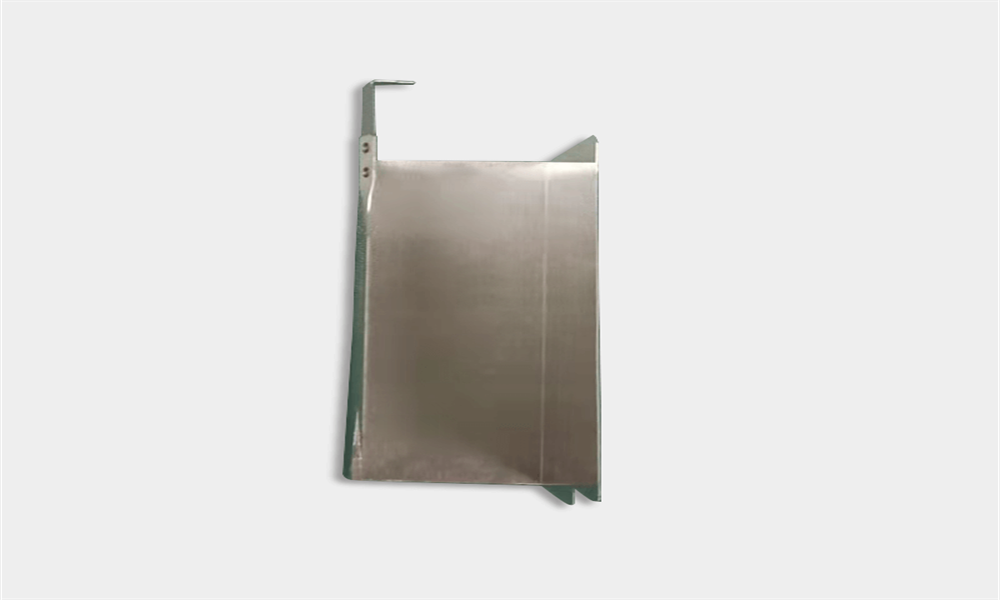

When designing metal stamping parts, the structure shall be easy to operate, safe, and reliable. In the process of metal stamping, as long as the workers' hands, arms, heads, and other parts stretch into the dangerous area, the stamping work can be completed successfully. Of course, the commissioning, installation, repair, handling, and storage of equipment are also very important, focusing on convenience and safety. Stainless steel hardware stamping.

As a metal stamping part, it is bound to have sufficient strength, so the material selection is reasonable

At the same time, the metal stampings formed at the same time shall not contact the external convex and concave products to avoid damage. When designing metal stampings, the location for installing mechanized devices shall be considered, so that mechanized and automatic devices can replace manual operation when necessary.

In the process of metal stamping, the structures such as the ejector, the pusher, and the stripper should be reliable, and other aspects should not cause potential safety hazards to the operators. With the cooperation of various requirements, metal stamping can be completed, and metal stamping parts with excellent quality can be obtained.

Further reading: The reason of precision influence of precision metal stamping parts

Feng-Yu is a China custom metal stamping manufacturer that was founded in 1971, based on our mastery of precision hardware processing technology and nearly 50 years of experience. Hardware processing provides key components for many industrial equipment and products, such as processing hardware stamping parts, injection molding parts, automotive stamping parts, precision hardware stamping parts, medical devices stamping, and other products. Our company provides a one-stop service process from drawing receiving to sample delivery, with stable quality and commitment, please contact us.

In the world of manufacturing and engineering, where precision reigns supreme, every component contributes to the final product's functionality, safety, and efficiency. Often overlooked yet essential, precision metal shims play a vital role.

In the world of electronics, power supply units (PSUs) play a critical role in converting electrical energy, ensuring devices receive the correct voltage and current for optimal operation. To safeguard their components and manage heat, PSUs require durable and efficient enclosures. This is where metal stamped power supply shells excel.

Custom-stamped appliance components are the backbone of products we rely on daily, from refrigerators to washing machines. To ensure appliances work efficiently and safely, these components must be manufactured to precise specifications. This involves challenges such as ensuring accurate dimensions and choosing materials with the right properties for each part.